Coil Coatings

Our Coil Coatings meet your commercial goals by drawing on research and development from laboratories across the world — in the Americas, Europe, Australia and Asia — to offer well proven products that combine innovative formulations manufactured to the highest quality standards.

Real-world exposure

Our product performance is proven with years of real-world experience at multiple outdoor test sites — exposing our products to the harshest conditions, which ensures they will stand up to the test of time. For decades we have been testing production samples of our coil and extrusion coatings at weathering facilities in South Florida and other locations around the world. These samples are constantly being evaluated to ensure their products are performing to the high levels expected of them.

Our real-world exposure program is the largest in the industry, with over 40,000 panels exposed to the elements in South Florida alone. We are regularly reviewing these test panels to make sure that we understand and can predict how they perform in the elements.

Performance on the line

In addition to making sure our products perform in the real world, we also constantly evaluate the performance of our products at our coater partners. We have a well-developed testing program designed to monitor the use of our products by coaters, which allows us to quickly respond to changes in the application environment. This results in products that are more reliable and trouble-free when being applied, with fewer costly issues and on-line adjustments.

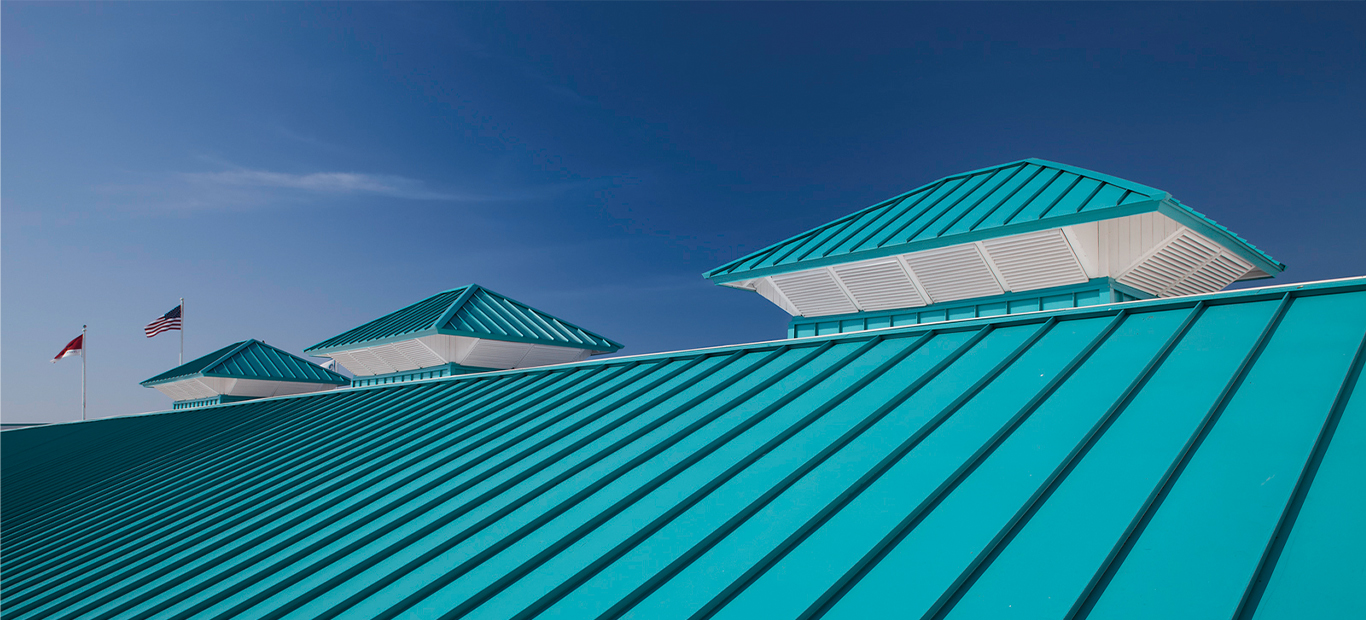

COOL CHEMISTRY

Our COOL CHEMISTRY products for roofing applications utilize ceramic and inorganic infrared reflective pigments. These special pigments are designed to reflect infrared energy while still absorbing visible light energy, thus appearing as the same color yet staying much cooler.

When COOL CHEMISTRY coatings are used on metal roofing, the result is a sustainable building material that can lower air conditioning costs, reduce peak energy demand, and help to mitigate urban heat island effects. When used on roofs and walls, COOL CHEMISTRY coatings can help reduce air conditioning costs by up to 15 percent in hot climates.

Long term durability needs to go hand-in-hand with the gains in energy efficiency that are possible with solar reflective pigments. COOL CHEMISTRY formulations offer the same exceptional resin technology as standard versions, along with the benefits of solar reflective pigmentation.