The critical role of weathering in coil and extrusion coatings

Exterior paints and coatings bring projects to life. To ensure these finishes will endure for years to come, it is critical to understand the performance of a coating when selecting high-quality materials for your next project. – That’s why AkzoNobel has developed our Global Weathering program for our Coil and Extrusion Coatings.

While accelerated weathering tests can provide early indication of how a coating will fare over time, real-world exposure remains the best indicator of long-term durability. AkzoNobel has been collecting performance data for over 30 years on our PVDF (polyvinylidene fluoride) and SMP (silicone-modified polyester) technologies. This extensive weathering program helps ensure our coatings provide robust protection against corrosion while resisting common issues like chalking, fading, and peeling. By monitoring performance factors like gloss and color retention, we can set industry-leading warranties that offer peace of mind and confidence to our customers, knowing their building materials will stand the test of time.

Environmental Factors

When selecting metal roofing and building components, several environmental factors must be carefully considered to ensure long-term performance. Direct UV exposure, especially on roofs, can cause fading and degradation of coatings, while moisture from rain or humidity can lead to corrosion and compromised structural integrity. In harsh and coastal environments, the presence of corrosive elements like salt or pollutants can further accelerate wear, making it critical to choose materials that can withstand these challenges over time.

Driving innovation through insight

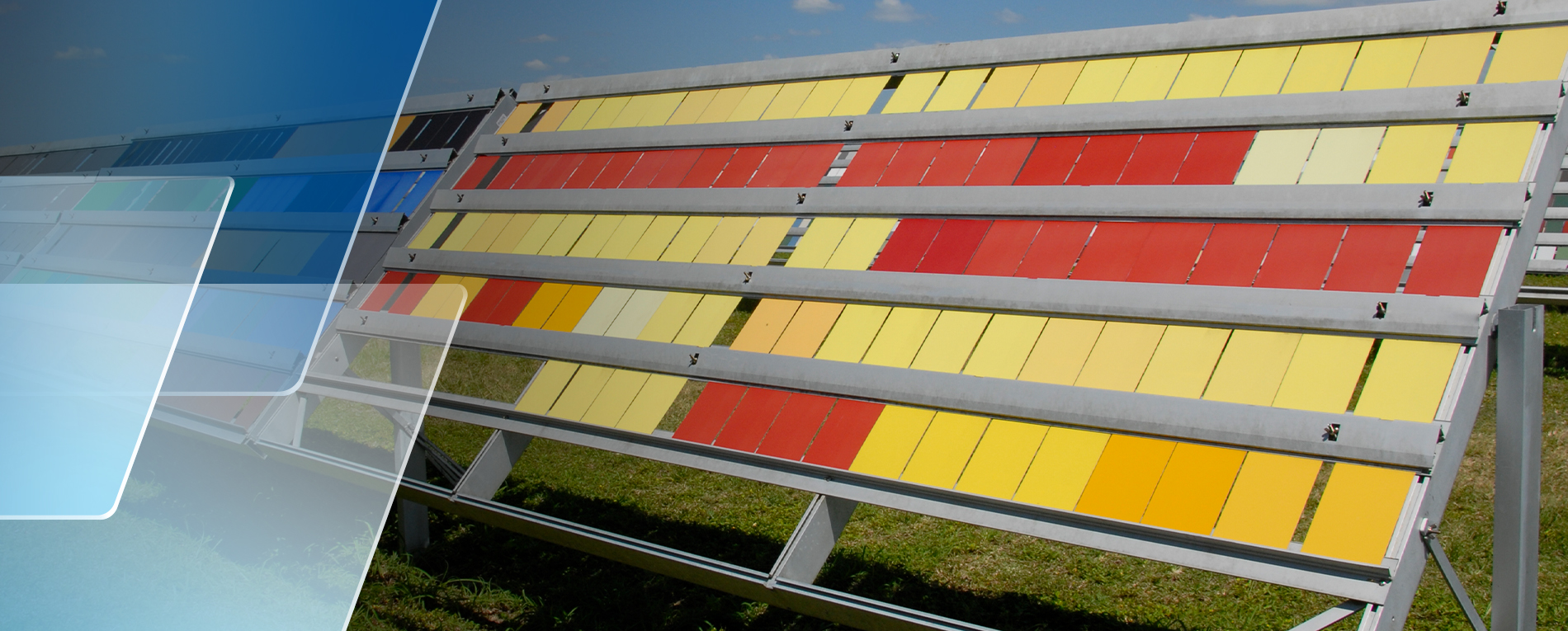

Through our Global Weathering Program, AkzoNobel’s product development team rigorously tests thousands of panels exposed to these harsh conditions, including coastal environments, for extended periods of time. We are constantly innovating, using the program to evaluate new technologies, as well as improve existing products.

Key performance attributes such as adhesion and resistance to corrosion, as well as color and gloss retention are tested. Additionally, we test coatings for resistance to chalking, monitor dirt pick-up and ease of cleaning, and conduct competitive evaluations to ensure our products consistently exceed industry standards and deliver superior protection.

Full System Performance

The full system performance of coil and extrusion coatings—comprising the substrate, pretreatment, primer, and topcoats—is critical to ensuring long-lasting protection and durability of building materials. The substrate must be properly cleaned and treated, and the primer forms the essential bond between the substrate and topcoat, while the topcoat provides the final layer of defense against environmental factors.

AkzoNobel’s primer, a polyester hybrid, offers superior UV resistance compared to competitive primers, enhancing the system’s overall longevity and protection. When paired with our best-in-class SMP and PVDF topcoats, your project is shielded by a system designed for excellent intercoat adhesion and long-term protection. The quality and performance of the coating are driven by the high-caliber materials we carefully select in our formulations. This includes resins that provide strength and flexibility, and advanced pigmentation for enhanced color retention and cool chemistry properties. The full system performance is evaluated through extensive laboratory tests, and our Global Weathering Program to ultimately deliver reliable, top-tier performance for any project.