IONOMY is leading this transformation

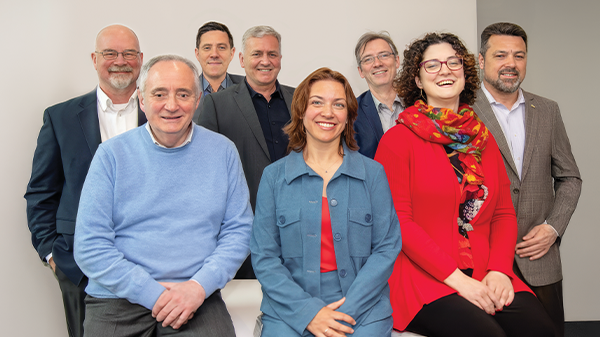

Led by AkzoNobel, the IONOMY ecosystem brings together world leading specialists in energy cure systems from coating chemists to equipment engineers, process designers, data analysts, and beyond. IONOMY is consultancy-led not-for-profit partnership that helps steel manufacturers and coaters make the shift from gas ovens to energy curing, not in theory, but in practice.

Even if your roadmap is unclear, we can help you navigate what’s coming. We’re ready to guide the industry’s shift to energy curing in ways that are commercially viable and strategically smart — cutting energy, cost, and waste, while making coating faster, more efficient, and delivering measurable curing-stage energy efficiency improvements for your business 1.

The ecosystem

The IONOMY ecosystem includes the following partners:

What we do

Deep diagnostic assessments

Tailored roadmaps for staged transformation

Effective turnkey solutions

On-site implementation and training

How we’re different

Know where you’re going.

And how to get there

We’ve reimagined the entire renewable energy curing journey—starting from the substrate up—to give you total clarity and control over your transformation. With a bold vision for the next era of coating, we equip you with a clear, proven process: from in-depth diagnostics to tailored solutions, pilot testing, seamless implementation, hands-on training, and continuous optimization. This isn’t just change. It’s precision-guided progress towards a new, more profitable business model.

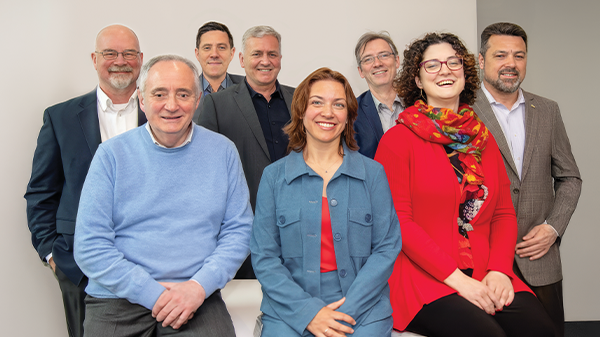

The revolution has a leadership team

IONOMY is a not-for-profit partnership, led by AkzoNobel, of world leading Energy Cure specialists, developers, consultants, manufacturers and suppliers that has been created to partner with you and guide you through uncertainty with confidence, expertise, and empathy. It addresses every aspect of the new logic from coating formulations, E-beam and UV systems, metal movement strategies, system control, software development and smart integration to deliver true turnkey solutions.

No templates.

Just transformation

There is no prescribed architecture and that’s by design. Whether you’re a steel producer, coater, specifier, or a new market entrant, your path to energy curing depends on challenges, constraints, and opportunities that are uniquely yours. We welcome that complexity, because revolutions are never linear. What matters isn’t where you start, but where we go together. With a shared vision and an adaptive mindset, we help you move forward without being boxed in by a rigid blueprint.

Advice without agenda

All revolutions come at a cost and embracing energy curing is no different. It is for the long term and capex investment will be necessary when you’re ready.

However, the consultancy, advice, guidance and design that IONOMY offers is entirely free. This is an opportunity to be at the vanguard of a revolution and one that we grasp with relish. With our help there will be a more profitable industry, with measurable curing stage energy efficiency gains 1,2.

1 Sustainability gains refer to curing-stage energy efficiency improvements compared to traditional curing methods. Wider lifecycle impacts may differ.

2 An example of an EU Commission supported project explores the benefits that can be achieved. See: https://cinea.ec.europa.eu/featured-projects/eb-uv-pre-painting-steel-coil-using-electron-beam-technology_en for more information.

3 The European Coil Coating Association (ECCA) estimates energy curing can reduce energy consumption in coil coating lines by at least 60% compared with traditional gas ovens See: More sustainable coatings: transitioning to lower energy consumption technologies | Arkema Global for more information

Energy transfer is just the start.

Business transformation is the outcome.

Frictionless transition

Future-aligned

End-to-end expertise

Clarity from complexity

Freedom to choose

Accessible expertise

How it works

• Proven methodology 2 starts with deep dive diagnostics across all technical, operational and commercial aspects before progressing to recommendations so your need determines your options.

• The process is consultative and starts with diagnostics and assessment and moves through solution design, road mapping and risk management to managed implementation, enablement and optimization.

• IONOMY operates as a non-commercial consultancy — you pay nothing for guidance and planning. There is no point trying to sell you new e-curable coatings before you have a line that can cure them.

1 Sustainability gains refer to curing-stage energy efficiency improvements compared to traditional curing methods. Wider lifecycle impacts may differ.

2 An example of an EU Commission supported project explores the benefits that can be achieved. See: https://cinea.ec.europa.eu/featured-projects/eb-uv-pre-painting-steel-coil-using-electron-beam-technology_en for more information.

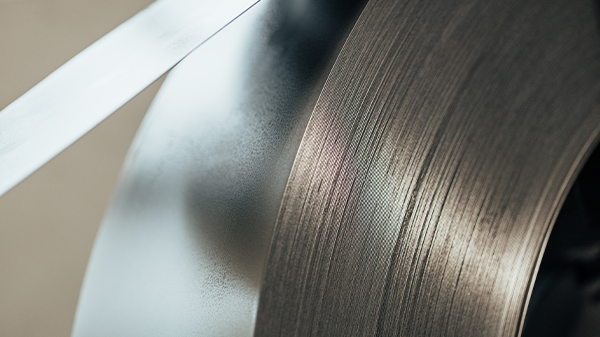

Transition to renewable energy cure for measurable, more sustainable benefits*

IONOMY can help the coil coatings industry reduce curing-stage energy use and related emissions, contributing to lower environmental impact while maintaining high performance standards through the transition to energy cure 1,2.

Full scale implementation may confirm and build on these findings; current evidence is based on pilot lines and desk based studies and should not be interpreted as industry wide proof.

Lower energy use

The European Coil Coating Association (ECCA) estimates energy curing can reduce energy consumption in coil coating lines by at least 60% compared with traditional gas ovens (ECCA, “Zero Carbon Coil Coating Line: The Way Forward”).

Enabling renewable electricity

By moving from gas to electricity, energy curing supports the transition to renewable energy sources, since renewable electricity is increasingly available in many regions.

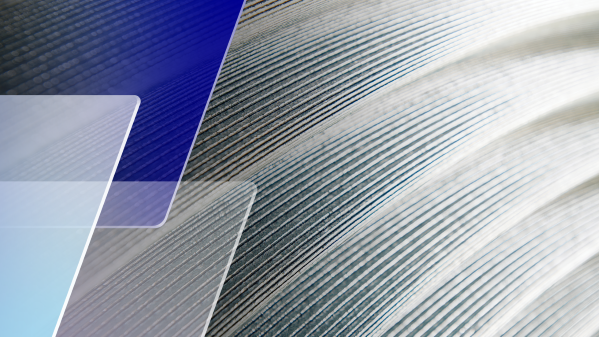

Advanced formulations

Since energy-cure coatings are high in solids, they contain little to no solvent, resulting in minimal or no emissions of volatile organic compounds (VOCs).

Less process waste

Energy curing allows instant line stoppage and restart. If a defect is identified, adjustments can be made immediately, reducing off-spec material and minimizing waste 1,2.

1 Sustainability gains refer to curing-stage energy efficiency improvements compared to traditional curing methods. Wider lifecycle impacts may differ.

2 An example of an EU Commission supported project explores the benefits that can be achieved. See: https://cinea.ec.europa.eu/featured-projects/eb-uv-pre-painting-steel-coil-using-electron-beam-technology_en for more information.

*For more information, see: https://www.arkema.com/global/en/resources/post/cs/transitioning-to-lower-energy-consumption-technologies/

How energy curing fits AkzoNobel commitments

Science-Based Targets

AkzoNobel’s carbon reduction targets – cutting emissions across our operations and value chain by 50% by 2030 (vs. 2018) – are validated by the Science Based Targets initiative (SBTi). The transition to energy curing with IONOMY is one of the levers being explored to support progress toward these goals.

Learn more about AkzoNobel's commitments:

Regulatory alignment

By reducing reliance on gas ovens in favor of electric energy curing in many applications, and cutting curing stage VOC emissions, energy curing supports compliance with current and future climate and air quality regulations across major regions (EU, US, Asia-Pacific).

Learn more about AkzoNobel's commitments:

Contribution to ESG goals

Lower energy consumption, reduced waste, and the elimination of organic solvents and their emissions all contribute to stronger environmental performance indicators, supporting your sustainability reporting and advancing progress toward ESG targets.

Learn more about AkzoNobel's commitments:

1 Sustainability gains refer to curing-stage energy efficiency improvements compared to traditional curing methods. Wider lifecycle impacts may differ.

2 An example of an EU Commission supported project explores the benefits that can be achieved. See: https://cinea.ec.europa.eu/featured-projects/eb-uv-pre-painting-steel-coil-using-electron-beam-technology_en for more information.

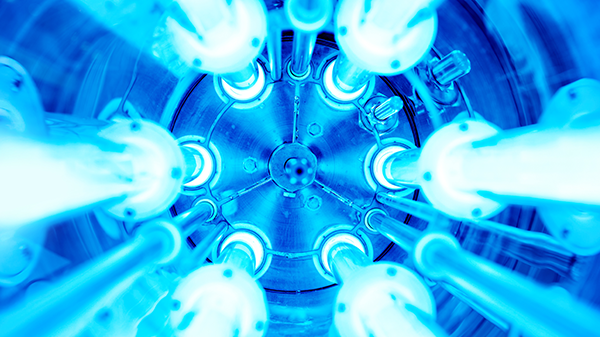

How energy curing works

Watch our video to learn how energy curing works

News, articles and more

Blog: Different paths, shared progress

The IONOMY™ ecosystem empowers businesses to transition to renewable energy curing without a one-size-fits-all approach. Every coil coating line is unique, so IONOMY offers flexible solutions—whether hybrid setups, partial upgrades, or complete conversions. It supports gradual integration to protect existing assets and minimize disruption. Through collaboration with experts, businesses can design tailored, scalable solutions that fit their goals. With IONOMY, transformation becomes practical, efficient, and confidence-driven.

Blog: Redefining progress in coil coating

The future of coil coating isn’t about moving alone—it’s about moving forward together. From renewable energy curing to integrated solutions, collaboration is driving transformation across the industry. Discover how the IONOMY™ ecosystem is making this vision a reality.

Live from METALCON 2025 with AkzoNobel!

Join Brent Fletcher as he sits down with MetalCoffeeShop for a lively interview covering industry insights, innovation, and more. Want to catch the IONOMY conversation? Jump to the 7-minute mark for a deep dive into how this game-changing partnership is shaping the future of energy curing.

AkzoNobel launches IONOMY™ ecosystem to help coil coaters overcome challenges of transitioning to renewable energy curing

Outdoor Durability of Radiation-Cured Coatings

In 2025, Michel Rosso, Scientist at the Expertise Center for Formulation & Analytical Science within our AkzoNobel Innovation Group, authored a peer-reviewed paper published in ScienceDirect.

Titled “Outdoor Durability of Radiation-Cured Coatings” the comprehensive article explores the main chemical, mechanical and environmental factors defining outdoor performance of radiation-cured (UV/EB) coatings. It also outlines the future research directions needed to further advance this important area of materials science, crucial to achieve real environment benefits and energy savings.

Sustainable innovation – reducing emissions through cutting-edge curing

There are many different factors in play when it comes to the energy transition. From innovative new ways to meet customer demands to streamlining our processes, each is equally important. Read how this is being embraced across AkzoNobel.

European Coil Coating Association (ECCA). Zero Carbon Coil Coating Line: The Way Forward study

The European Coil Coating Association (ECCA) is an international non-profit association dedicated to the promotion of the use of prepainted metal as the environmentally sound, the cost effective and the high quality method of finishing.

It estimates that energy curing can reduce energy consumption in coil coating lines by at least 60% (compared with traditional gas ovens) based on its Zero Carbon Coil Coating Line: The Way Forward study.

1 Sustainability gains refer to curing-stage energy efficiency improvements compared to traditional curing methods. Wider lifecycle impacts may differ.

2 An example of an EU Commission supported project explores the benefits that can be achieved. See: https://cinea.ec.europa.eu/featured-projects/eb-uv-pre-painting-steel-coil-using-electron-beam-technology_en for more information.